Die VV-DV Serie: Belüftungstrockner zur Vermeidung von Feuchteschäden in Hydraulik & Getrieben mit langen Stillständen & unregelmäßigen Wartungsintervallen.

Keine Korrosion im Tank

Kein Qualitätsverlust der Betriebsflüssigkeiten

Empfohlen für Anlagen mit geringer Atemfrequenz

Geeignet für den Innen-, Außen- und Offshore-Einsatz

Einweg-Variante

Einfach austauschbarer Einweg-Adsorber.

ATEX

Nicht geeignet für Exlosionsschutzzonen.

Offshore geeignet

Geeignet für den Einsatz in Salzluft.

REACH konform

Sicheres und unbedenkliches Produkt.

RoHS konform

Sicheres und unbedenkliches Produkt.

IP Schutzklasse

IP 66

UV Resistenz

Hoch

Betriebstemperatur

-40°C bis +80°C / 125°C

Korrosivitätsklasse

C5

Material

Polyamid (PA), Polycarbonat (PC), Polyvinylchlorid (PVC), FKM, GIEBEL Xdry®, Aktivkohle

Geeignete Substanzen

Hydrauliköl, Getriebeöl, biologisches Öl, Pflanzenöl, Transformatorenöl, Isolieröl, AdBlue (Harnstoff), Dieselkraftstoff, Isocyanate, Polyole, Anhydrit

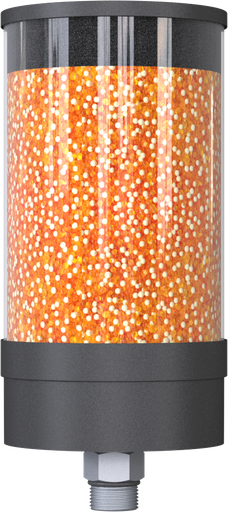

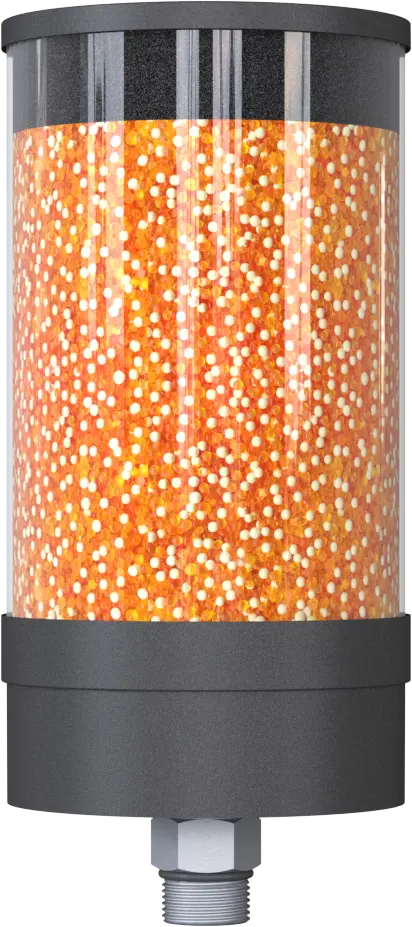

Adsorberkomponenten und ihre Aufgaben.

Plastic housing (A): Protects the inner workings of the adsorber. The disposable plastic housing is durable and UV-resistant.

Activated carbon disk (B): Adsorbs oil particles and aerosols from exhaust air. The activated carbon layer not only protects the desiccant from contact with oil, but also prevents harmful oil mist from escaping the system.

3µm paper filter (C): Filters finest dust and dirt particles from supply air and thus protects the system from getting filthy.

GIEBEL Xdry® (D): Ensures effective drying of the air flowing through and indicates by changing color from orange to green when it is time to replace the adsorber.

Slosh protection (E): Prevents oil splashes and small oil droplets from escaping. They condense on the slosh protection and drip back into the system.

Foam filter disk (F): Filters coarse dust and dirt particles from the supply air.

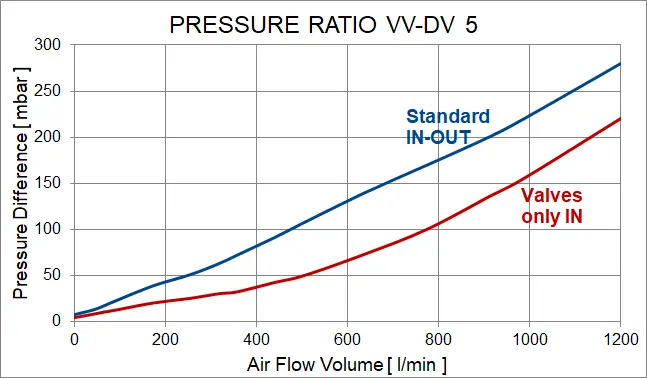

Valve (G): Enables air exchange with the environment when the system draws in or pushes out air for pressure equalization and at the same time protects the desiccant from unnecessary loading while the system is at a standstill.

Thread (H): Connects system and adsorber. Various thread types are available.

ADSORPTION PROCESS:

If the oil level in the system drops, air flows in to equalize pressure. This air enters the adsorber via the openings (G) and flows through a coarse filter (F), which separates larger dirt and dust particles. The GIEBEL Xdry® filling (D) then separates moisture up to 2% RH (average 10% RH). A 3μm filter (C) removes even the finest dirt and dust particles from the supply air.

Dry and clean air enters the system.

DESORPTION PROCESS:

If the oil level rises, air is pressed out of the system. This air contains oil particles and aerosols. Larger oil particles condense on the oil demister (E) and drip back into the system. Finer oil particles and aerosols are separated by the activated carbon (B). Some of the previously adsorbed moisture is removed from the desiccant as the air flows out, ensuring cyclical self-regeneration.

Clean air escapes the system.

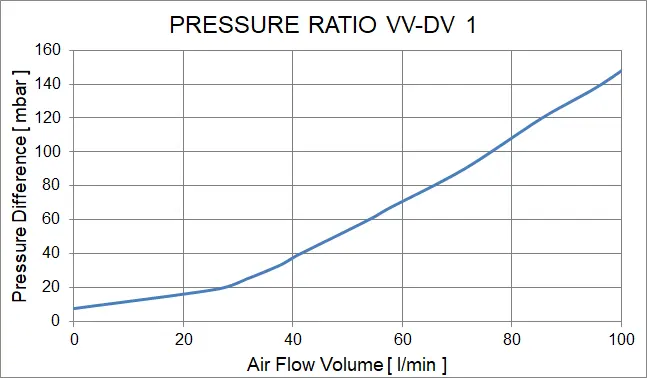

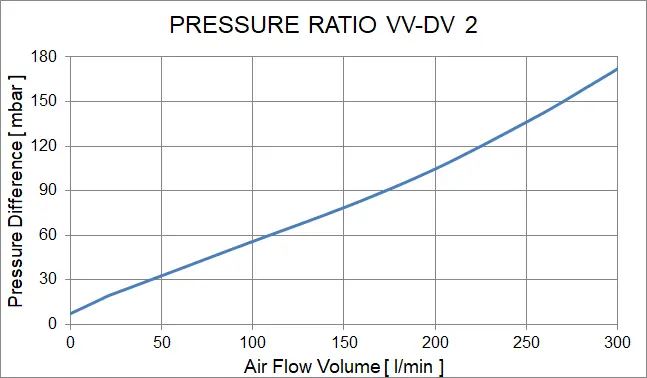

Technical data according to size.