VV-D Adsorber: Instructions according to DIN82079.

Section 1: Information on the manufacturer

Section 2: Product overview

Section 3: Construction & material

Section 4: Technical data

Section 5: Assembly & commissioning

Section 6: Maintenance

Section 7: Spare parts & storage

Section 8: Disposal

Section 9: Risk & hazard analysis

Section 10: Maintenance plan

Section 1: Information on the manufacturer.

Giebel FilTec GmbH

Carl-Zeiss-Str. 5

74626 Bretzfeld

Germany

(+49) 79 46 9444 01-0

info@gf-dry.com

Section 2: Product overview.

Materials used

Polyamide(PA), polycarbonate (PC), polyvinylchloride (PVC), FKM, GIEBEL Xdry®, activated carbon

REACH Note

No ingredients requiring disclosure under Regulation (EC) No 1907/2006

Section 3: Construction & materials.

Section 4: Technical data.

Section 5: Assembly & commiccioning.

Section 6: Maintenance.

Section 7: Replacement & storage.

If the disposable adsorber is completely saturated, it must be replaced by a new one.

Section 8: Disposal.

At the end of its useful life, the device must be disposed of in accordance with the relevant legal regulations. The fully loaded adsorber can be disposed of in household waste. GIEBEL Xdry® is not classified as a hazardous substance under European Union legislation (Regulation EC No 1272/2008). It is not subject to compulsory labelling according to EC Directive (67/548/EEC or 1999/45/EC). GIEBEL Xdry® is not classified as a substance hazardous to health or the environment.

Section 9: Risk & harzard analysis.

1. Moist air flows into the system

Porous seals

Moist air can flow into the adsorber or into the plant at the porous points. As a result,

complete drying is not possible and moist air enters the system.

Saturated drying agent

When the desiccant is saturated, it can no longer absorb moisture. This allows moist air to

enter the system.

Air flow rate too high

If the air flow rate is too high, the contact time between moist air and desiccant is too

short. This allows moist air to flow into the system.

Oil on the drying agent

If too many oil particles enter the adsorber, the oil particles close the pores of the

desiccant and thus prevent adsorption.

Ambient temperature too high

If the ambient temperature exceeds 80°C, the binding forces in the desiccant decrease. As

a result, the incoming ambient air is only dried to a limited extent.

2. Positive or negative pressure builds up in the system

Air flow rate too high

Too high an air flow rate can cause over- or underpressure in the system.

Contaminated filter element

The filter unit can be clogged by dirt particles and can therefore build up pressure in the

system.

Oil on the drying agent

If oil particles get into the adsorber, the spaces in the fill can be filled with oil and the fill

will stick together. This can cause pressure to build up in the system.

3. Adsorber is damaged

Material resistance

When selecting the adsorber, the ambient and operating conditions should be considered.

An aggressive environment or liquid in the container can damage the adsorber.

Temperature range

The ambient and operating temperatures should not exceed or fall below the specified

range, otherwise the adsorber may be damaged.

Improper handling

Incorrect or improper handling can damage the adsorber. Please pay attention to the

recommended installation.

Strong vibrations

Strong vibrations of the plant can damage the adsorber.

Pressure range of the system

The adsorber should not be exposed to a positive or negative pressure above 0.5 bar,

otherwise the housing may be damaged.

Cleaning of the adsorber

For external cleaning of the adsorber, the use of a mild soap in combination with water is

recommended. The use of brake cleaner will damage the adsorber and is no reason for

complaint.

Section 10: Maintenance plan.

Check seals for wear

Cycle: Half yearly

Check

The O-ring installed on the adsorber must be checked for perfect condition. For this purpose, the seal at the connection should be checked for brittleness.

Measures

In case of existing damage, a new O-ring or a new adsorber should be used.

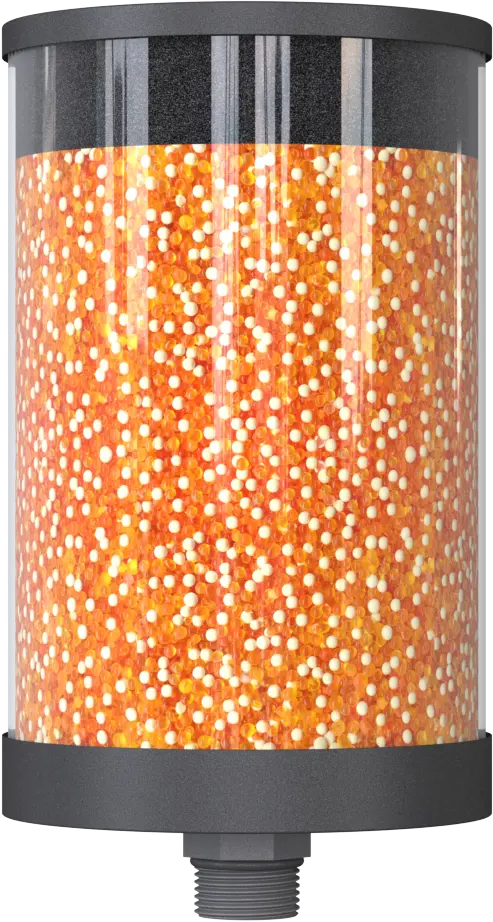

Visual inspection of the desiccant

Cycle: Half yearly

Check

The loading condition of the desiccant must be determined by visual

inspection of the adsorber. The color orange indicates that the silica gel can

still adsorb water and air is dehumidified. If the desiccant is completely

saturated, the color changes to green or colorless.

If there are oil particles on the desiccant, these close the pores and the

adsorption capacity is reduced. This causes the desicant to discolor more

slowly and unevenly

Measures

If the desiccant is loaded or damaged by oil, a new adsorber with fresh

desiccant should be used.

Visual inspection of the adsorber

Cycle: Yearly

Check

The adsorber, including the connection, must be visually checked for damage. Damage can occur due to various environmental or operating conditions.

Measures

If the adsorber is damaged, it must be completely replaced to ensure full functionality.