Die VV-D Serie: Belüftungs-trockner zur Vermeidung von Feuchteschäden

in Hydraulik, Getrieben, Fässern & IBC mit konstantem Luftaustausch & kurzen Wartungsintervallen.

Keine Korrosion im Tank oder Fass

Kein Qualitätsverlust der Betriebsflüssigkeiten

Minimaler Druckaufbau, auch bei hohen Durchflussraten

Geeignet für den Innen-, Außen- und Offshore-Einsatz

Einweg-Variante

Einfach austauschbarer Einweg-Adsorber.

ATEX

Nicht geeignet für Exlosionsschutzzonen.

Offshore geeignet

Geeignet für den Einsatz in Salzluft.

REACH konform

Sicheres und unbedenkliches Produkt.

RoHS konform

Sicheres und unbedenkliches Produkt.

IP Schutzklasse

IP 63

UV Resistenz

Hoch

Betriebstemperatur

-40°C bis +80°C

Korrosivitätsklasse

C5

Material

Polyamid (PA), Polycarbonat (PC), Polyvinylchlorid (PVC), FKM, GIEBEL Xdry®, Aktivkohle

Geeignete Substanzen

Hydrauliköl, Getriebeöl, biologisches Öl, Pflanzenöl, Transformatorenöl, Isolieröl, AdBlue (Harnstoff), Dieselkraftstoff, Isocyanate, Polyole, Anhydrit, Klebstoffe, Harze, Amine, PU-Metallkatalysatoren, Flammschutzmittel, Diethanolamin, Silikon

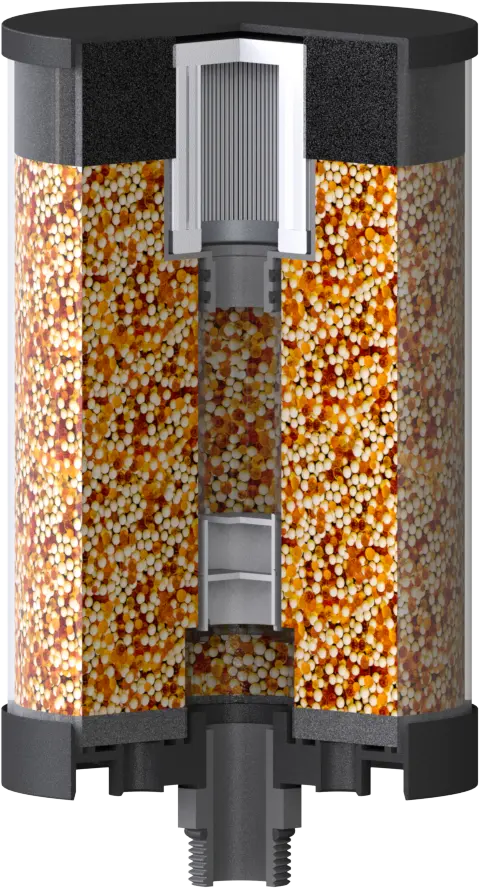

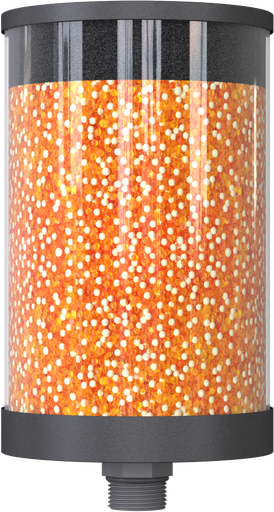

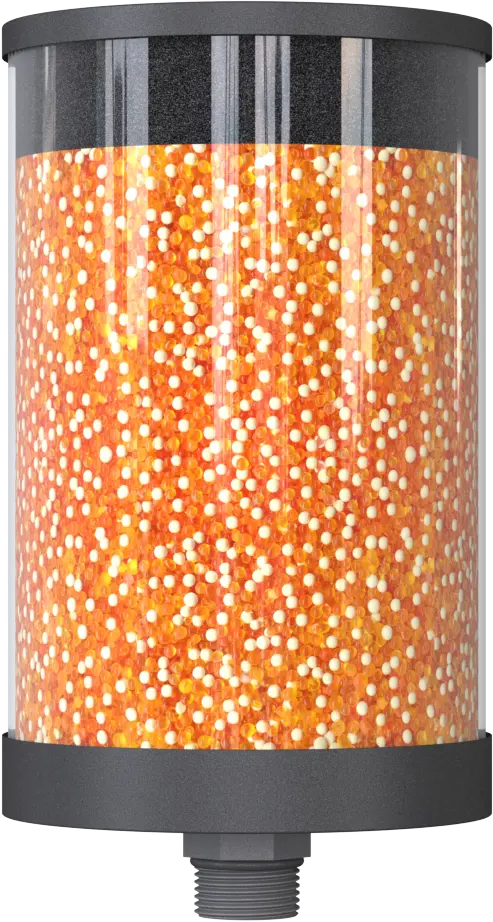

Adsorberkomponenten und ihre Aufgaben.

Kunststoffgehäuse (A): Schützt das Innenleben des Adsorbers. Das Einweg-Kunststoffgehäuse ist langlebig und UV-beständig.

Aktivkohlescheibe (B): Adsorbiert Ölpartikel und Aerosole aus der Abluft. Die Aktivkohleschicht schützt nicht nur das Trocknungsmittel vor dem Kontakt mit Öl, sondern verhindert auch, dass schädlicher Ölnebel aus dem System entweicht.

3µm Papierfilter (C): Filters finest dust and dirt particles from supply air and thus protects the system from getting filthy.

GIEBEL Xdry® (D): Filtert feinste Staub- und Schmutzpartikel aus der Zuluft und schützt so das System vor Verschmutzung.

Schwappschutz (E): Verhindert das Austreten von Ölspritzern und kleinen Öltropfen. Diese kondensieren am Spritzschutz und tropfen zurück in das System.

Schaumstoff-Filterscheibe (F): Filtert groben Staub und Schmutzpartikel aus der Zuluft.

Öffnungen (G): Ermöglicht den Luftaustausch mit der Umgebung, wenn das System Luft zum Druckausgleich ansaugt oder ausstößt.

Gewinde (H): Verbindet System und Adsorber. Es sind verschiedene Gewindetypen erhältlich.

ADSORPTIONSPROZESS:

Wenn der Ölstand im System sinkt, strömt Luft ein, um den Druck auszugleichen. Diese Luft gelangt über die Öffnungen (G) in den Adsorber und strömt durch einen Grobfilter (F), der größere Schmutz- und Staubpartikel abscheidet. Die GIEBEL Xdry®-Füllung (D) scheidet daraufhin Feuchtigkeit bis zu 2 % rF (durchschnittlich 10 % rF) ab. Ein 3-μm-Filter (C) entfernt selbst feinste Schmutz- und Staubpartikel aus der Zuluft.

Trockene und saubere Zufluft.

DESORPTIONSPROZESS:

Wenn der Ölstand steigt, wird Luft aus dem System gedrückt. Diese Luft enthält Ölpartikel und Aerosole. Größere Öltropfen kondensieren am Schwappschutz (E) und tropfen zurück ins System. Feinere Ölpartikel und Aerosole werden durch die Aktivkohlescheibe (B) abgeschieden. Ein Teil der zuvor adsorbierten Feuchtigkeit wird beim Austritt der Luft aus dem Trockenmittel entfernt, wodurch eine zyklische Selbstregeneration gewährleistet ist.

Saubere Abluft.

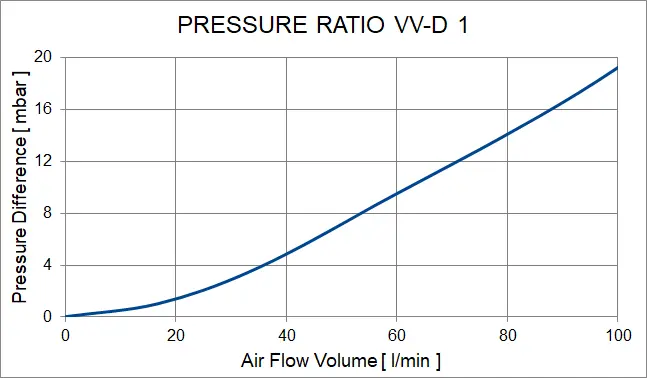

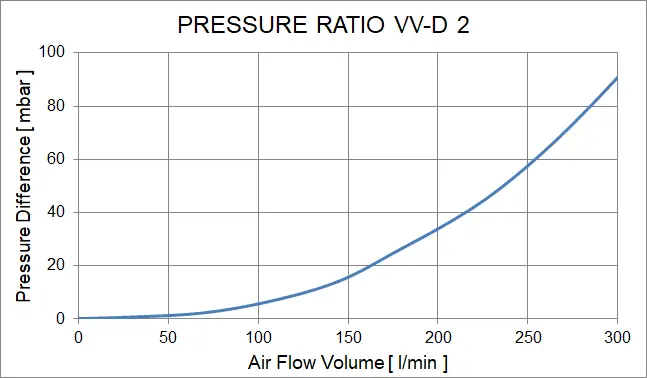

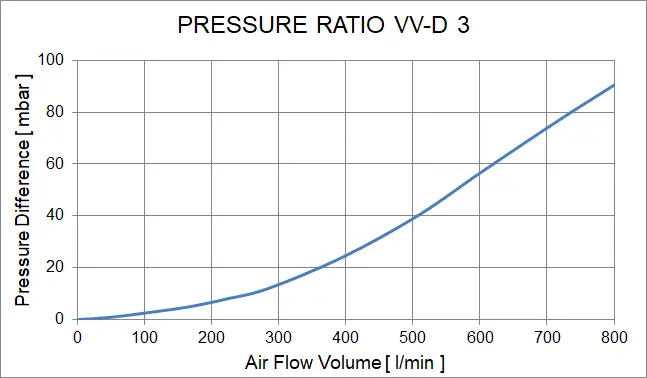

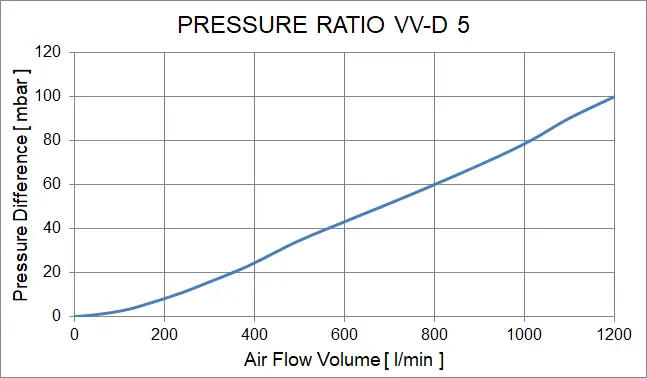

Technische Daten nach Größe.

Pressure ratios.