The MS-R series: Breather dryers to prevent moisture damage in large storage tanks with a capacity of more than 60cbm.

No corrosion inside your storage tank

No quality degradation of contained substances

Suitable for use in explosion protection zones according to ATEX 2014

Refillable

Sustainable multiple-use adsorber.

ATEX conform

Suitable for explosion protection zones.

Offshore suitable

Suitable for use in salty air.

REACH compliant

Safe and harmless product.

RoHS compliant

Safe and harmless product.

IP protection class

IP 63

UV resistance

Very high

Operating temperature

-40°C to +80°C / 160°C

Corrosivity class

CX

Material information

Stainless steel, polycarbonate (PC), FKM, GIEBEL Xdry®

Suitable substances

Hydraulic oil, gear oil, biological oil, vegetable oil, transformer oil, insulating oil, AdBlue (Urea), diesel fuel, isocyanates, polyols, anhydrite, flammable liquids (fuels, solventsetc.), sulphuric acid, benzenesulphonic acid, dichloromethane, methanol, caustic soda

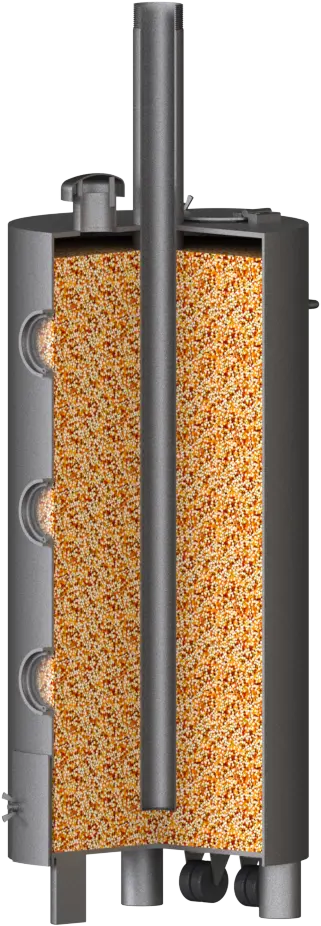

Adsorber components and their tasks.

Metallic housing (A): Protects the inner workings of the adsorber. The refillable stainless steel housing is suitable for harsh environments, explosion protection zones and offshore use and is highly UV-resistant.

GIEBEL Xdry® (B): Ensures effective drying of the air flowing through and indicates by changing color from orange to green when it is time to replace the adsorber.

Filter cap (C): Enables air exchange with the environment when the system draws in or pushes out air for pressure equalization.

Thread (D): Connects system and adsorber.

Filling flap (E): Enables easy refilling of the desiccant.

Emptying flap (F): Enables easy removal of the desiccant when it is saturated.

ADSORPTION PROCESS:

When the oil level in the system drops, air flows in to equalize the pressure. This air enters the adsorber via the filter cap (C) and flows through the GIEBEL Xdry® filling (B), where moisture up to 2 % RH (average 10 % RH) is separated.

Dry air enters the system.

DESORPTION PROCESS:

If the oil level rises, air is pressed out of the system. Some of the previously adsorbed moisture is removed from the desiccant as the air flows out, ensuring cyclical self-regeneration.

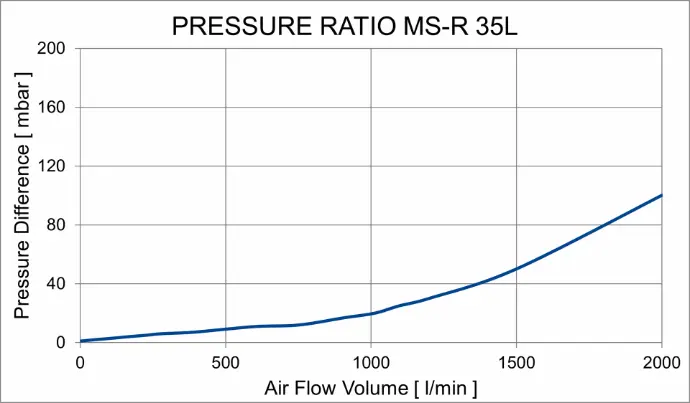

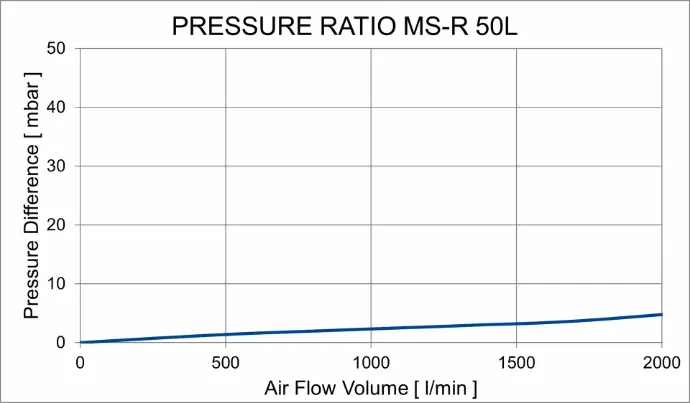

Technical data according to size.