How do breather dryers work?

Breather dryers save you nerve-racking, time-consuming, and costly maintenance work. Let’s explore how they do this, and why they are essential for protecting machines and fluids.

Where the trouble starts ...

If you look closely, you will notice that most damage to machines is caused by moisture and dirt entering a system - slowly and unnoticed. Let us explain.

Hydraulics, gearboxes, barrels & IBCs, storage tanks, and transformers —they work on the same principle: If the oil level drops, air flows in to equalize pressure. If the oil level rises, air is forced out. It's an ongoing cycle.

But while air leaves the tank with the next rise of the oil level, some moisture and dust remain. Reasons for this are the hygroscopic operating oil, which attracts and binds water, and the formation of condensate when temperatures drop —for example, during shutdowns or when the system itself is exposed to temperature fluctuation. Condensate drips into the oil, dust settles on the oil surface. And with a little time passing by, rust forms on the corners of the tank, highly abrasive particles break off and trickle into the oil.

... & where things really get dicey.

Water, dust, and rust are a dangerous combination. The water content in the operating oil affects the viscosity, lubricity, and shear stability. Dust leads to sludge deposits. And rust triggers a chain reaction in oil contaminated with water and additives, forming free radicals that attack the hydrocarbon chains and form acids that further accelerate oil decomposition.

What happens when this oil travels through the system? With higher flow properties friction points are no longer supplied with the necessary amount of hydraulic oil – this causes abrasion and wear. The oil becomes more viscous – this puts strain on the drive units of the system and reduces efficiency. Residues clog valves, sludge formation increases the need for filters, and increasing acidification increases the risk of corrosion of all metal components and attacks the seals.

You change the valves, install new filters, replace the oil and damaged components. Each time, you spend money and spend hours on maintenance work – and the cycle starts all over again.

Displacement

If the oil level in the system drops, air flows in to equalize pressure.

Separation

This air enters the GIEBEL VV-RV adsorber via the opening and flows through a foam filter disk, which separates larger dirt and dust particles.

Adsorption

The GIEBEL Xdry® filling then separates moisture up to 2% RH (average 10% RH).

Filtration

A 3μm paper filter removes even the finest dirt and dust particles from the supply air.

01

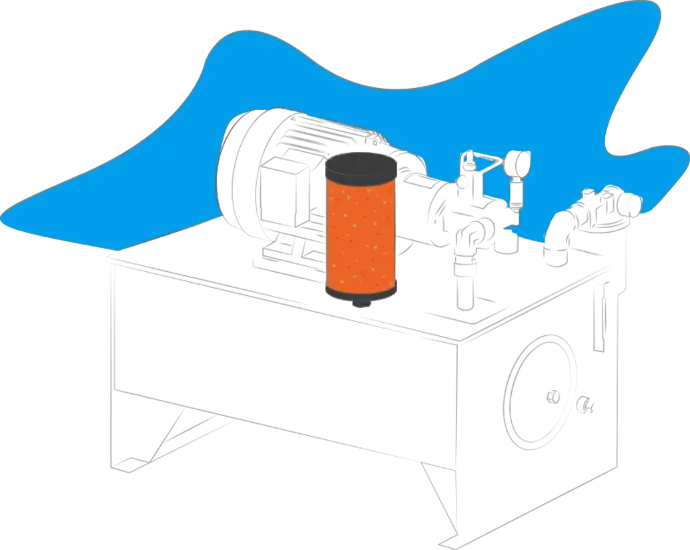

Your machine equipped with an adsorber is exposed to humid ambient air.

02

The oil level drops and air flows in to equalize pressure. The adsorber separates moisture down to 2%rh (10%rh on average) and filters out dust particles. The system remains dry.

03

The oil level rises, air is pressed out to equalize pressure. The adsorber prevents oil fumes from escaping through the carbon inside. In addition, the air flow removes some of the previously stored water from the adsorber, thus ensuring cyclical self-regeneration.

FAQ regarding adsorbers in general.

Malfunctions & troubleshooting

Adsorption is a physical process in which atoms or molecules, known as the adsorptive, attach to the surface of a material called the adsorbent. This can take place in both gas phase and liquid phase systems, depending on whether the surrounding fluid is a gas or a liquid.

Adsorption is critical for maintaining the performance and reliability of hydraulic systems, gearboxes, barrels & IBCs, storage tanks, and transformers. It helps reduce downtime, extend equipment life, and improve operational efficiency.

GIEBEL Adsorbers® are engineered to prevent condensation inside hydraulic systems, gearboxes, storage tanks, barrels & IBCs, and transformers. As systems breathe during operation or temperature changes, moisture can enter and condense internally, causing corrosion, oil degradation, and system failures.

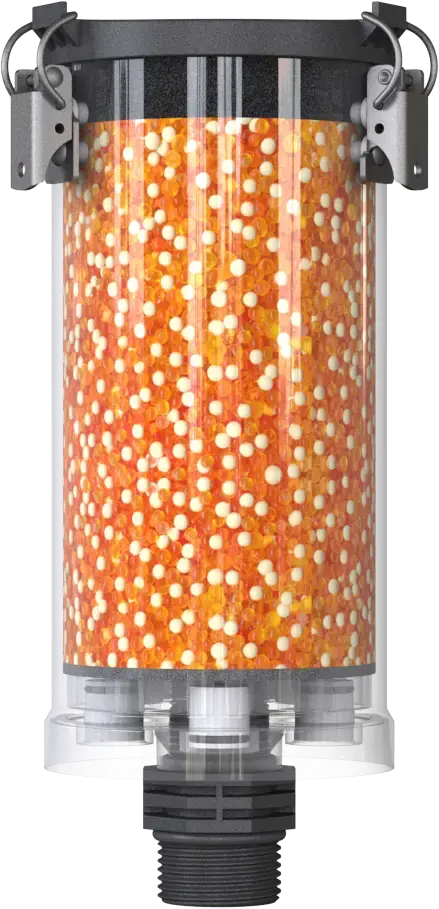

Each adsorber is filled with GIEBEL Xdry®, our high-performance desiccant mixture that adsorbs moisture before it can enter the system. This stops condensation at the source. With integrated particle filters, GIEBEL Adsorbers® also block contaminants, ensuring clean and dry system conditions and extending the service life of your equipment.

GIEBEL Adsorbers® are used in a wide range of systems where preventing condensation and contamination is critical. These primarily include hydraulic units, gearboxes, storage tanks, barrels & IBCs, transformers.

Any system that exchanges air with its environment is at risk of moisture entering and condensing inside. GIEBEL Adsorbers® prevent this by adsorbing moisture and filtering particles before they can enter the system, making them essential for maintaining reliability and extending the service life of equipment across many industries.

GIEBEL Adsorbers® are made from high-quality materials designed to withstand harsh environments and provide long-lasting protection. Each unit includes a durable housing, which can be made from aluminum, stainless steel, or plastic depending on the application. Inside, the adsorber is filled with GIEBEL Xdry®, our desiccant mixture that effectively adsorbs moisture from the air.

To ensure complete system protection, every adsorber also includes integrated particle filters that block dust and contaminants. Depending on the model, optional accessories can be attached to meet specific system requirements. Every component is selected to deliver reliable performance and keep systems clean and dry.

GIEBEL offers both rechargeable and disposable adsorbers, each with a different approach to maintenance.

Rechargeable adsorbers can be serviced when the desiccant becomes saturated, as indicated by the color change of GIEBEL Xdry® from orange to green. These units are designed to be opened and refilled with fresh desiccant, and many models are supported with spare part kits containing replacement seals, filters, and other components to ensure full restoration of performance.

Disposable adsorbers are replaced entirely once the desiccant is saturated. GIEBEL Xdry ® does not contain cobalt dichloride or other toxic substances, making our disposable units safe to handle and environmentally friendly during disposal.

Regularly monitoring the desiccant color and replacing or servicing the adsorber as needed ensures continuous protection from condensation and contamination across all applications.

We care about you & your machinery!

REQUEST A CALL BACKMore than 16,000 companys trust GIEBEL Adsorbers® to keep their plants dry and clean.

Every year, our aeration dryers keep around 13,200 liters of water out of machines and storage tanks - to prevent them from being damaged.

Annually, our oil mist separators capture around 900 liters of oil in the form of aerosols - to protect people and the environment.